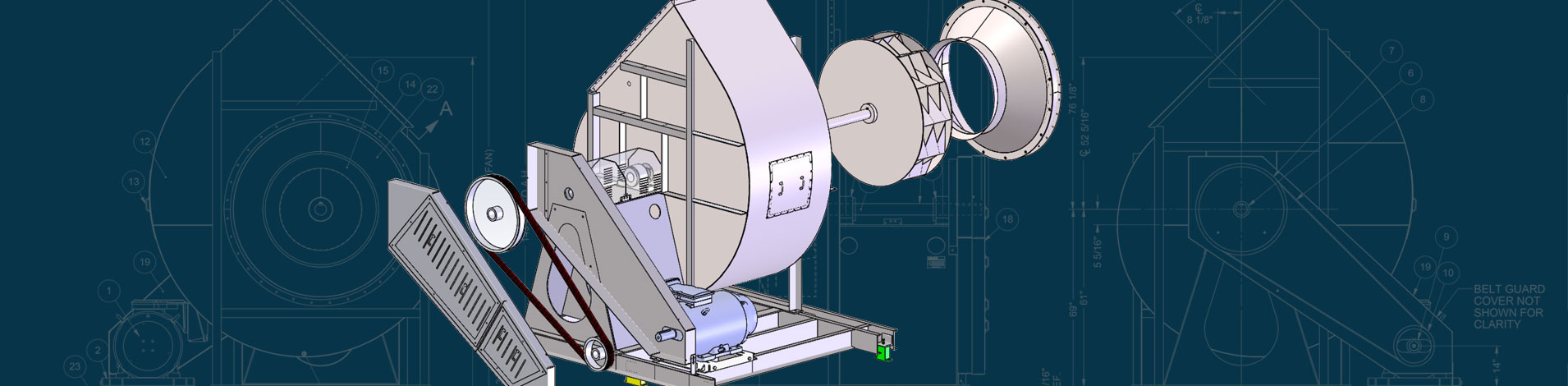

Special and Custom Products

IATC understands that not every air handling system is the same. There are many more factors beyond pressure and volume flow that go into choosing the right fan for your application. Whether your application involves high temperature, wet, abrasive, volatile, material handling or chemical laden airstreams, IATC engineers can help select the right fan style and features to provide a robust and long lasting fan.

Stress and Frequency Analysis

Some fan applications require non-standard wheel designs. Temperature or airstream content may require the use of special materials. Efficiency or performance requirements may necessitate the use of special wheel geometry. The application may require a range of run speed free from wheel natural frequencies.

The IATC engineering team uses finite element analysis tools to calculate the stress distribution of these special wheels. It is important to confirm that the design meets our safety requirements at maximum speed. The natural frequency response of the wheel is examined to make sure there is not a resonant frequency at the fan’s design speed. Some customers using variable frequency drives require a range of operating speeds free of resonant frequencies. This often requires specialized design to tune the wheels for the application.

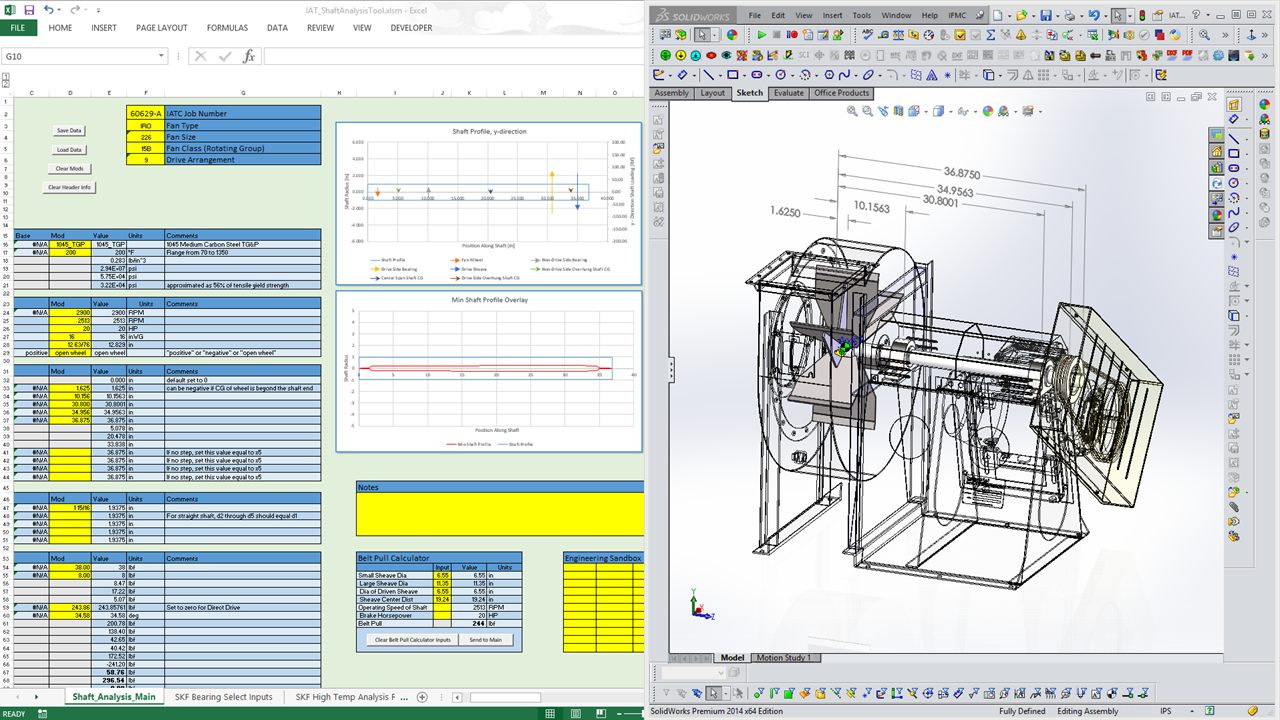

Bearing and Shaft Analysis

IATC engineering reviews bearing load and life calculations for each fan produced. Re-lubrication intervals are also recommended based on the speed and application of the fan.

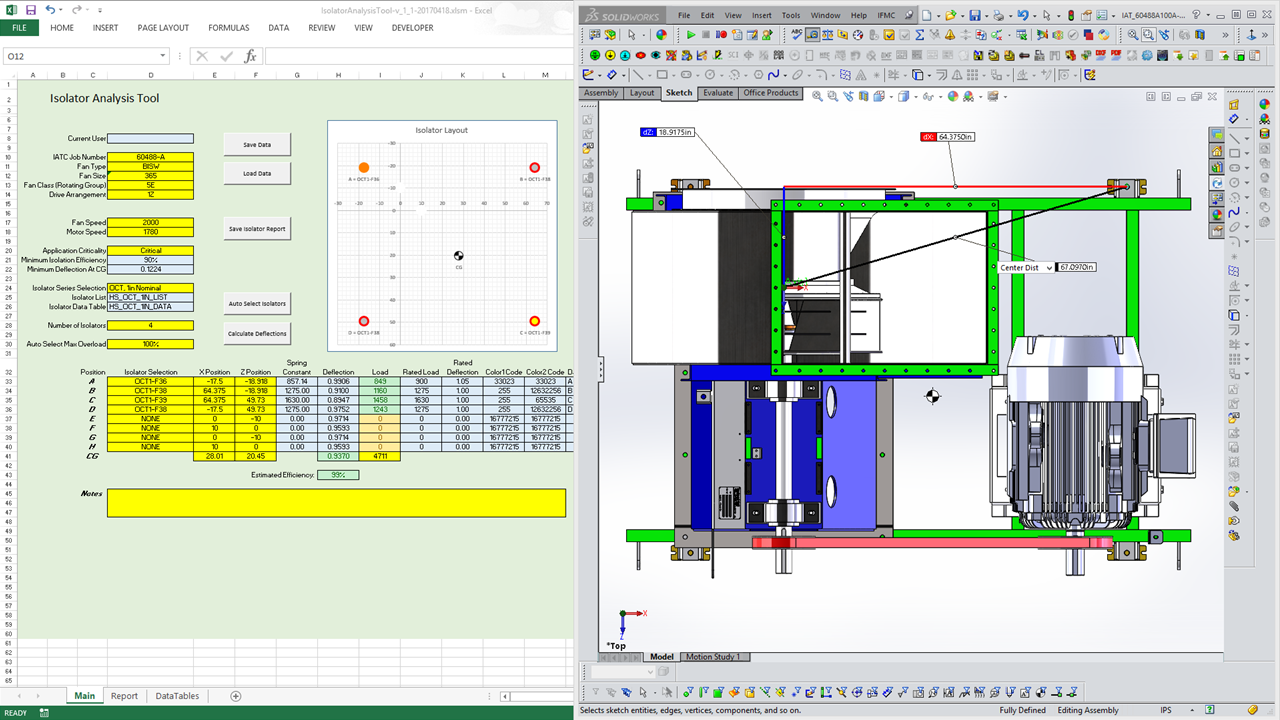

Vibration Isolation

Some customer applications require the use of vibration isolators. IATC engineering selects the isolators for each fan based on its weight, center of gravity and operating speeds to obtain the most efficient and effective vibration isolation possible.