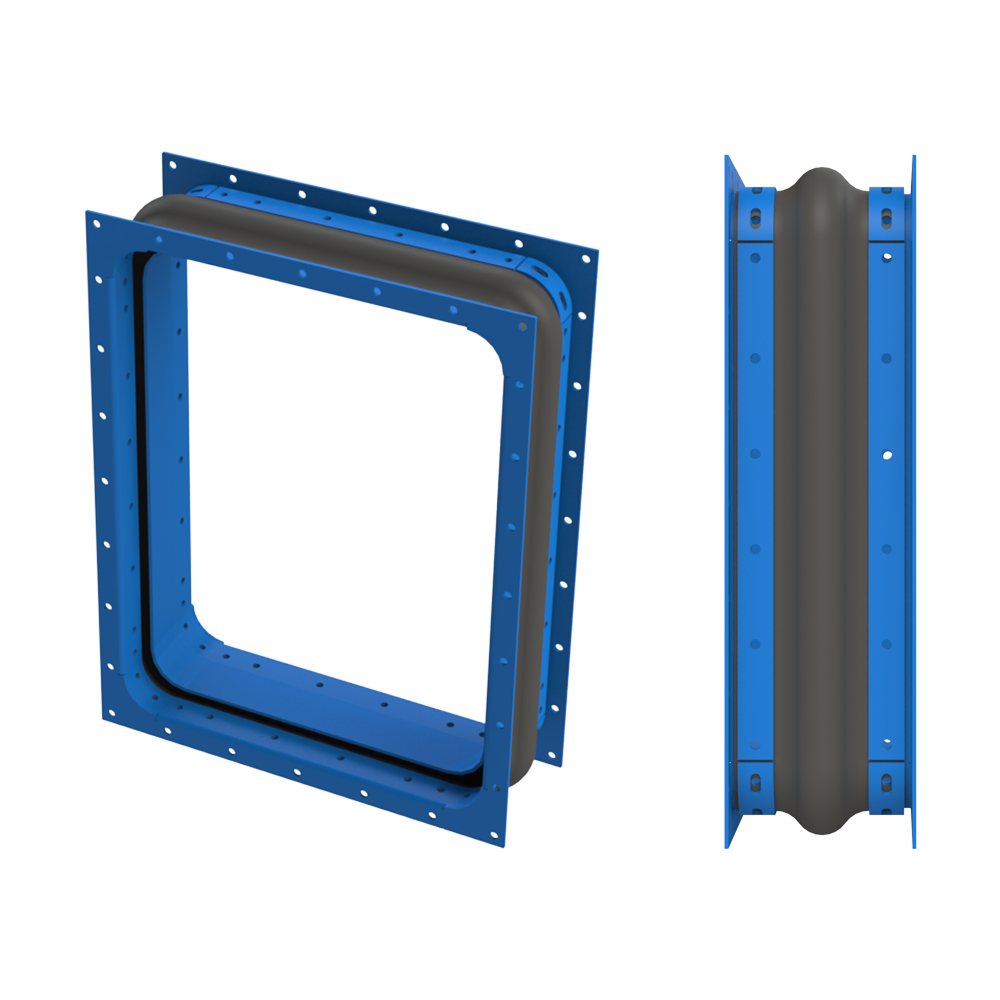

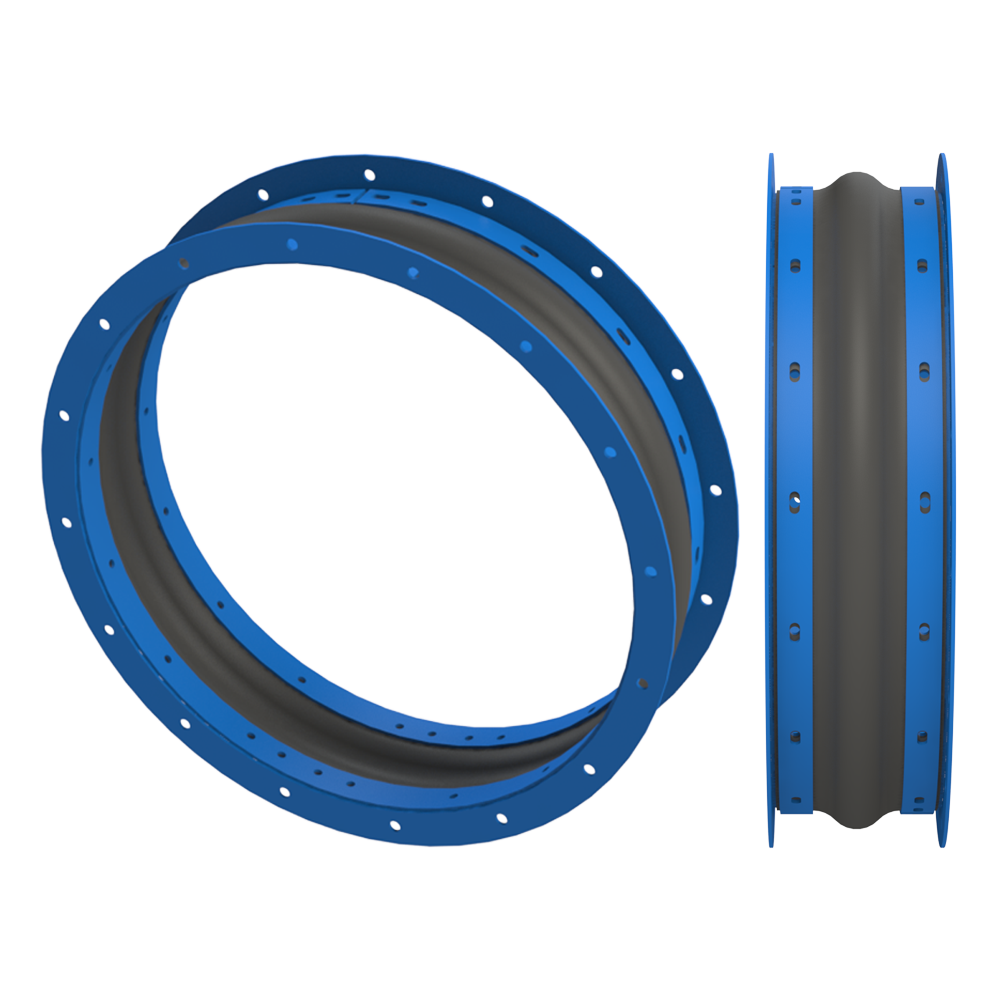

Shown with flow liner

Shown without flow liner

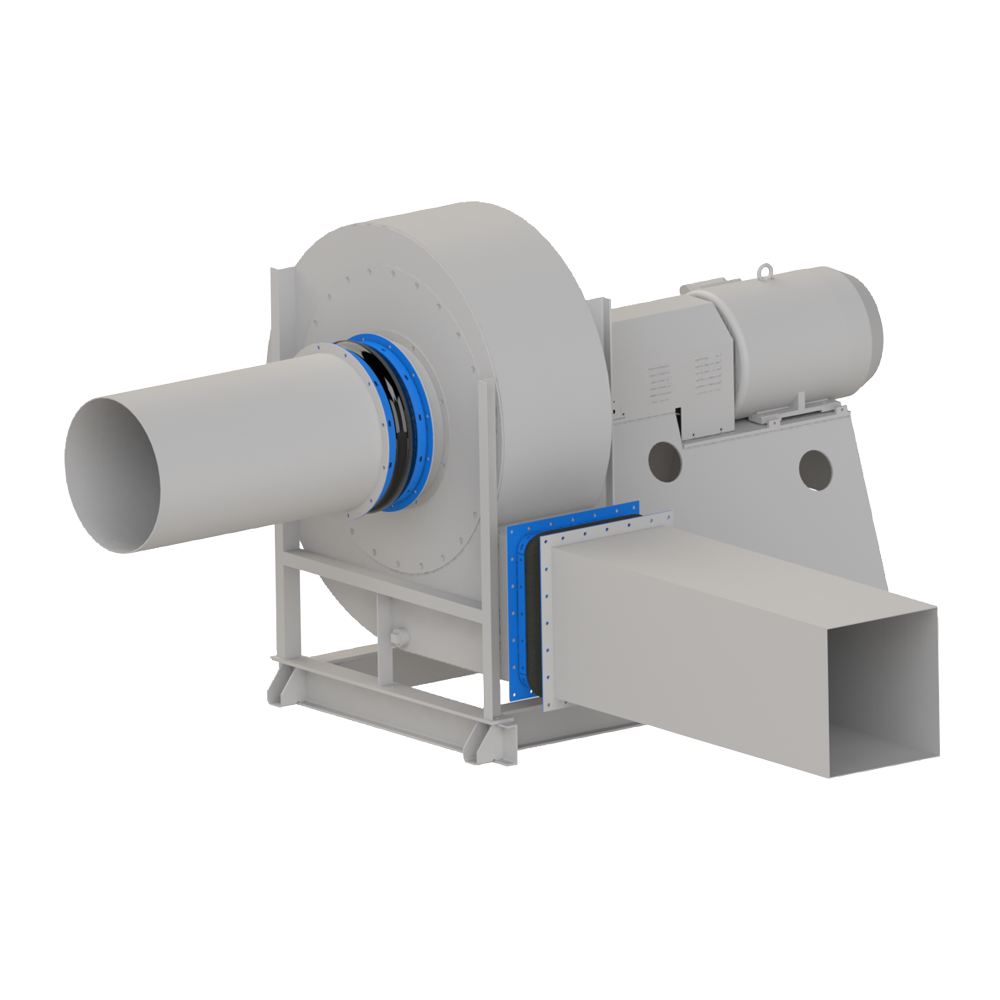

Flexible Connectors are useful for a variety of purposes in air handling systems.

- To isolate weight and wind loading on fan housings imposed from stacks, ductwork, and silencers.

- To isolate the transmission of vibration on inlets and outlets of fans and ductwork.

- To allow for minor axial, radial, and rotational misalignment of duct or piping connections to fan inlets and outlets.

- To accommodate expansion of components due to temperature

Shown with Flex Connectors between fan and ductwork

Shown with Flex Connectors between outlet silencer, and inlet box damper and inlet duct

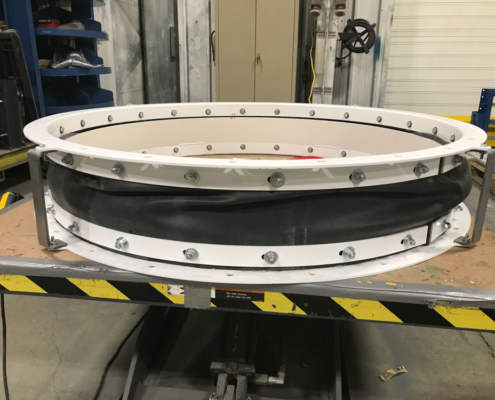

Flex material comes in a variety of compounds to accommodate airstream material content and temperature. For negative pressure applications, dirty airstreams or higher velocity flow rates, flex connectors often require internal deflectors to protect fabric. Flow liners also provide improved airflow thru the flexible connector reducing aerodynamic inefficiencies. Flanges and deflectors are constructed from carbon steel, zinc plated carbon steel, aluminum, and stainless steel.

Options

Flex Material

- EPDM (225 deg. maximum)

- Fiberglass reinforced Silicone (500 deg. Maximum)

Flanges and Flow liners (deflectors)

- Carbon Steel (Standard)

- Zinc Plated Carbon Steel

- Stainless Steel

- Aluminum

Paint

- Standard IATC Powder Coat Blue Enamel

- Custom Enamel

- Hi-Temperature Zinc rich

- Epoxy