The IATC Industrial Silencer Series is suitable for many medium to heavy-duty industrial applications where it is desirable to reduce the air turbulence noise emanating from an air handling system. Introducing only a modest pressure drop to the system, these silencers provide good sound absorption characteristics at the medium and high noise frequencies generated by a centrifugal fan. These Dissipative (Absorptive) Silencers are the classical solution for fan noise attenuation and other industrial noise control in up to 450-degree air stream conditions. Typical noise reduction applications include, fan inlet silencers, fan outlet silencers, duct silencers, and exhaust fan silencers.

IATC Construction Features:

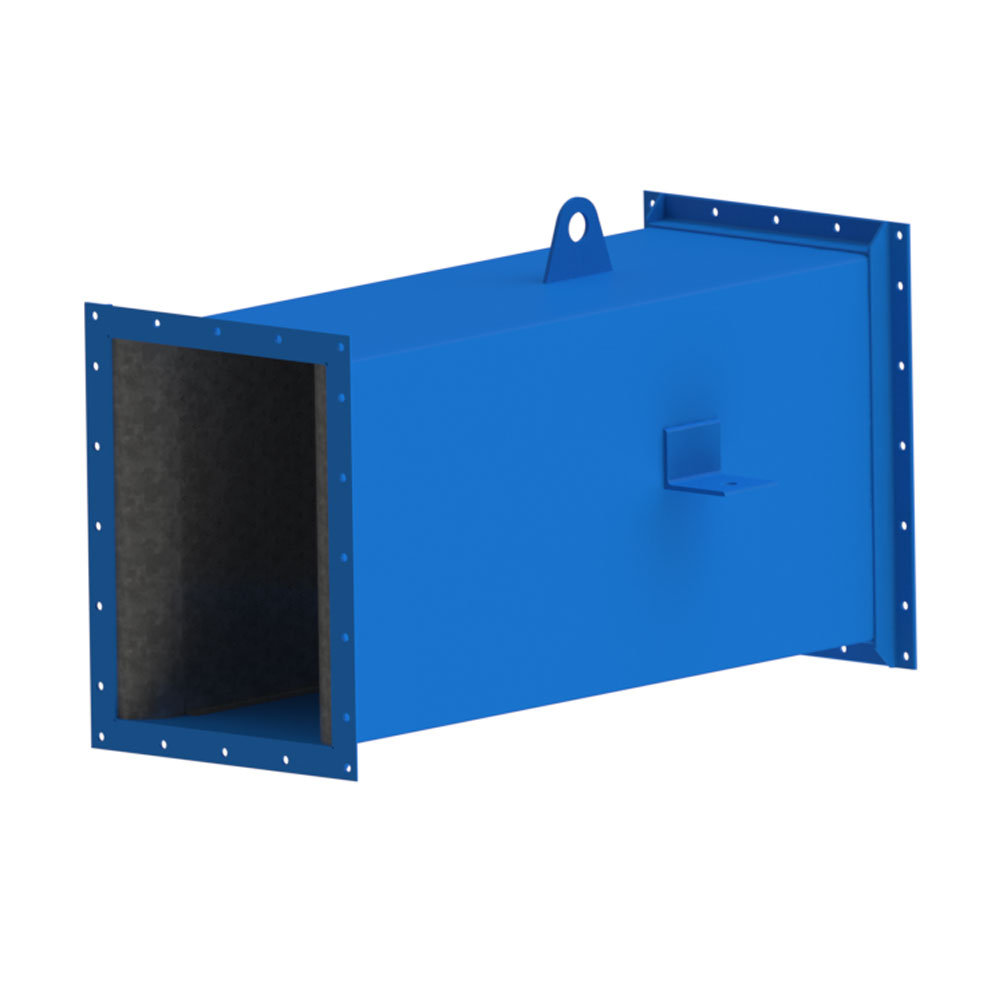

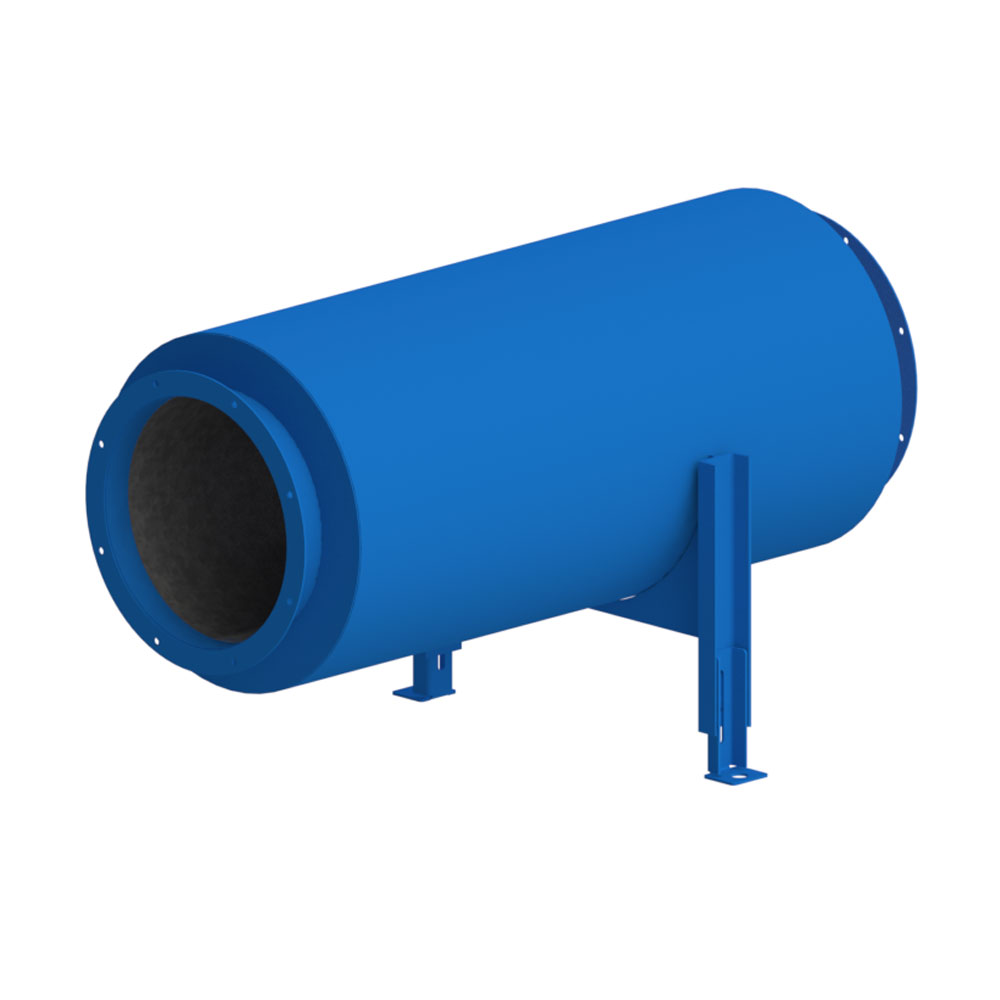

- 12 gauge shell construction standard for most models (up to 3/8” thick)

- Lifting Lugs

- Support Brackets

- Welded Construction

- Fiberglass Acoustic Media covered with Fiberglass Cloth or Mylar

Available Options:

- Custom flange bolt patterns

- Inlet and Outlet Screens

- Weather Hoods

- Access Doors

- Drains

- Adjustable Support Legs (a silencer is not to be supported by a fan)

- Stainless Steel Construction

- Paint Finishes: Enamel, Epoxy, Zinc Rich, High Temperature, Powder Coat

Inlet Silencer

Outlet Silencer

Typical Models

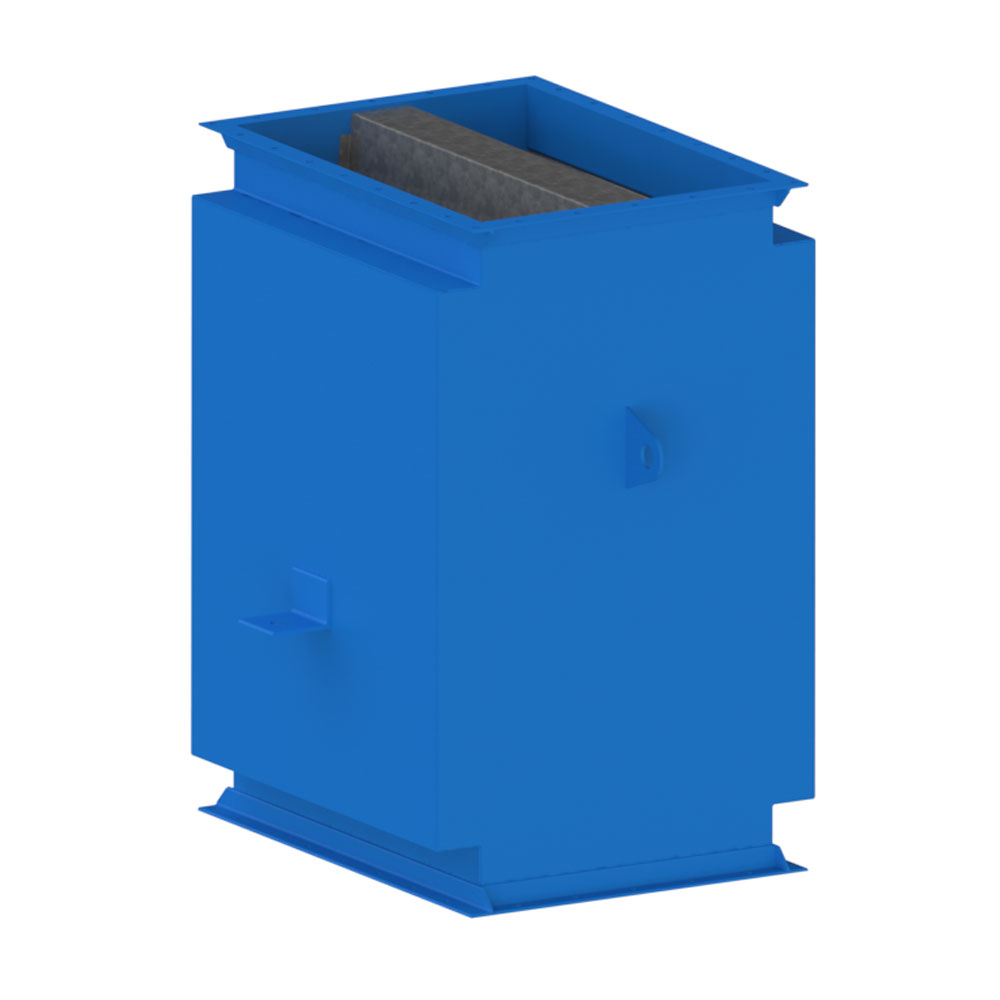

VROS – Vertical Rectangular Outlet Silencer

VROS – Vertical Rectangular Outlet Silencer

VROS – Vertical Rectangular Outlet Silencer

VCOS – Vertical Cylindrical Outlet Silencer

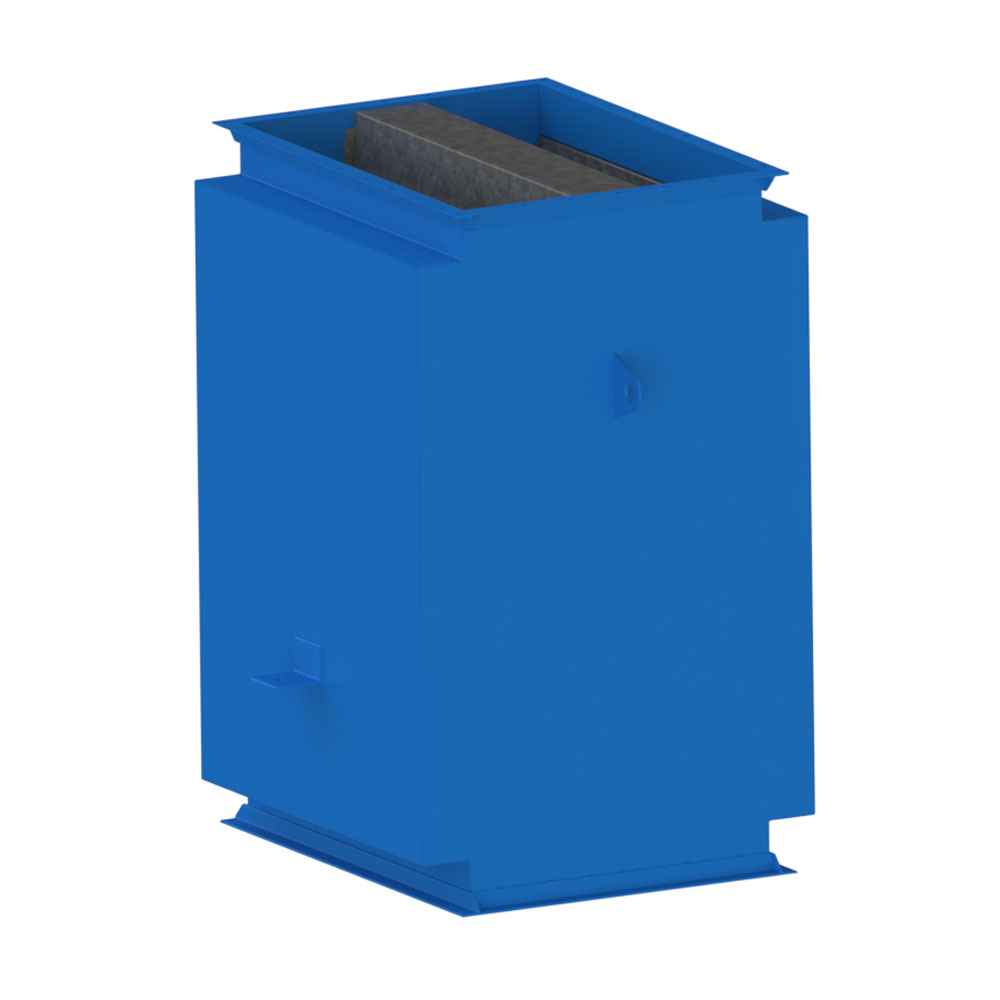

VIBS – Vertical Inlet Box Silencer

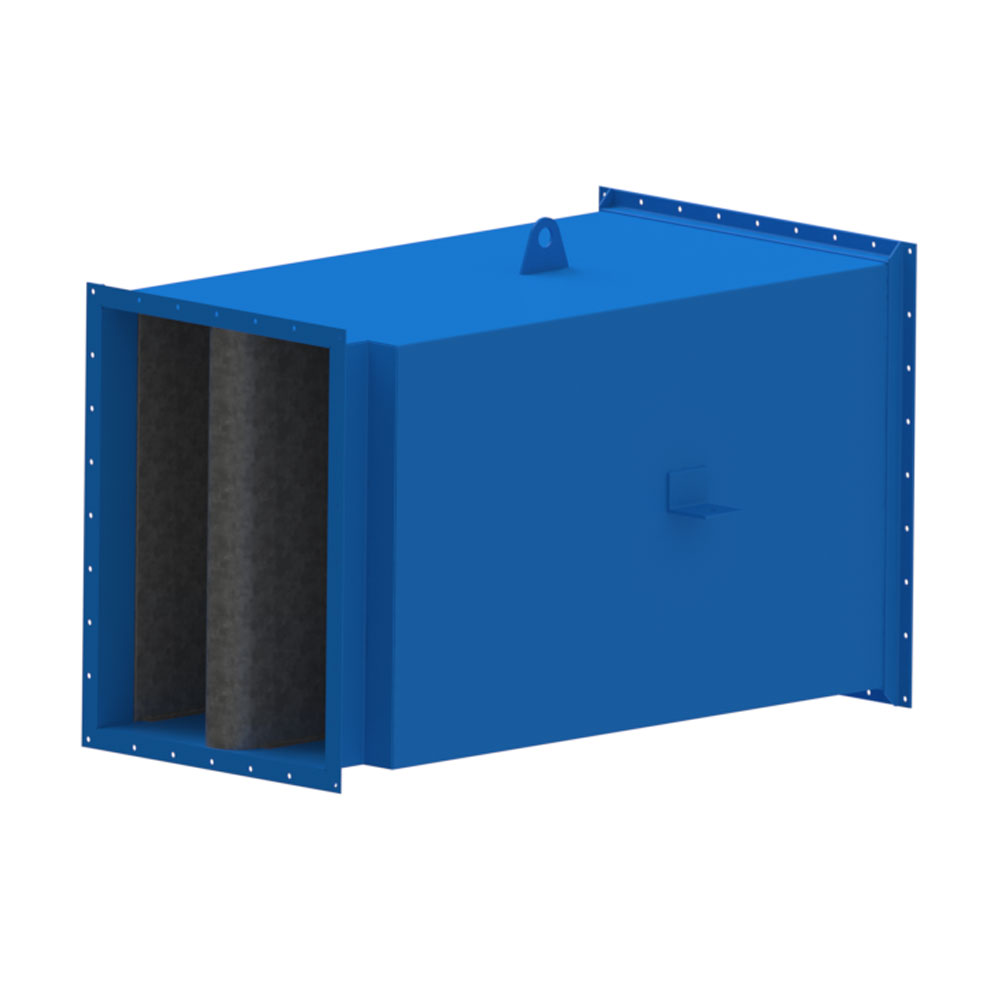

HRIS – Horizontal Rectangular Inlet Silencer

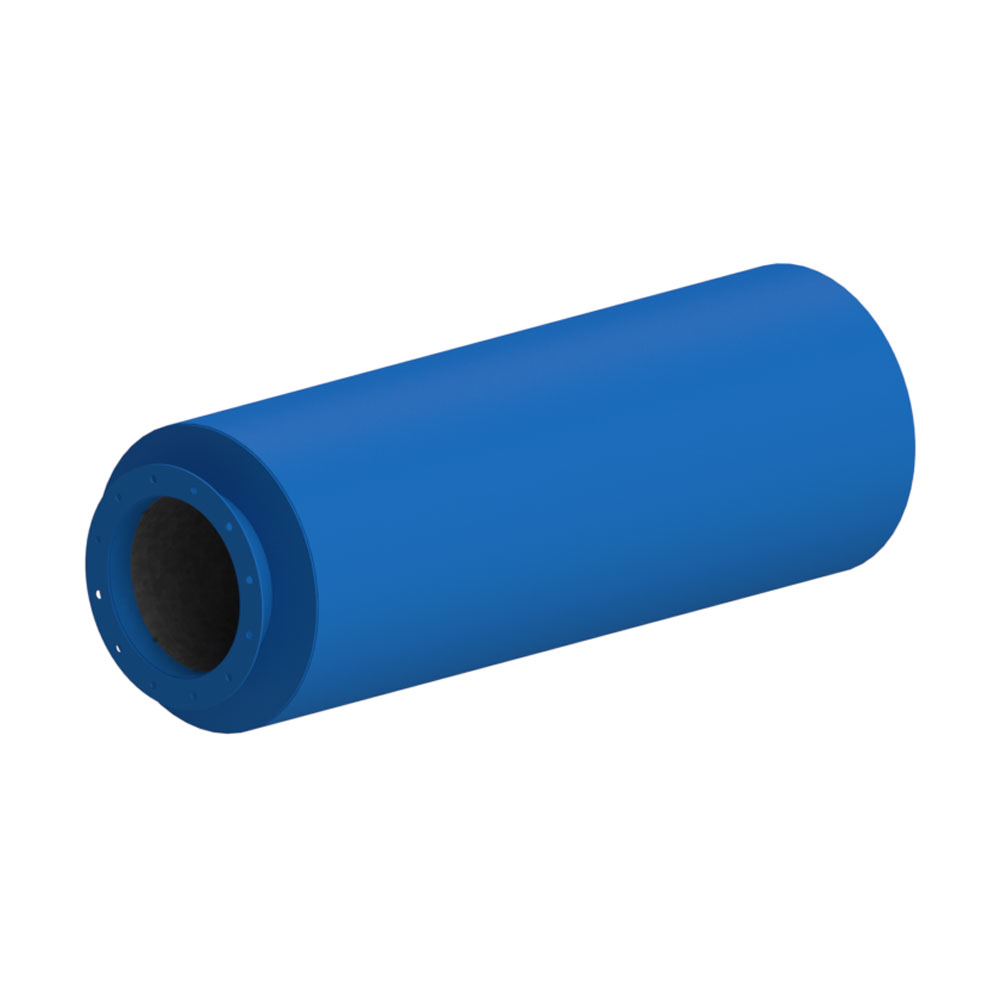

HCIS – Horizontal Cylindrical Inlet Silencer

HROS – Horizontal Rectangular Outlet Silencer

HCOS – Horizontal Cylindrical Outlet Silencer

Typical Fan Silencer Configurations

Silencers are available for fan inlets and outlets as well as other industrial ductwork applications.

*Note. In vertical applications, silencers should be supported to prevent loading on the fan housing from stack or duct weight, and wind loading. In some instances, installing a flexible connector between the fan and the silencer is recommended.

Silencer Selection and Design

Noise entering a silencer is defined as sound power and measured in decibels (dB) according to eight designated frequency bands. The silencer will absorb and dissipate the noise in each frequency band by a predictable amount depending on the silencer design, resulting in reduced sound power. The sound power exiting the silencer is then manipulated for distance, directivity (reflection from nearby surfaces), end of duct reflections, and “A” scale weighting to arrive at a numerical noise pressure level. This sound pressure level is also measured in decibels, but because it has been adjusted to the “A” scale, is further designated as dBA. Because the airstream passing over the silencing elements will generate noise and because the silencer wall is also subject to breakout noise, those values are also evaluated to ensure that they are insignificant relative to the silenced airstream.

A properly designed silencer will meet the following criteria:

- Acoustic: The silencer must be able to reduce incoming sound power by the desired amount with respect to frequency band, expressed as the Dynamic Insertion Loss (DIL). The environment in which the silencer will operate must be known since the acoustical performance is significantly affected by temperature, gas characteristics, system configuration and physical layout.

- Aerodynamic: Airflow through a silencer will cause a pressure loss and will impact acoustic performance

- Geometrical: The silencer must fit in the space that is available

- Mechanical: Minimal maintenance should be required to keep a silencer operating near full efficiency for long periods of time. Sufficiently durable modifications to the silencer design must be available to allow it to handle elevated temperatures as well as exotic gases which may erode less durable materials.

- Economical

Because these criteria are often in conflict with each other, it is important to work with a silencer vendor who understands industrial fan applications. IATC can help you find a solution in which all of the criteria are fulfilled to a satisfactory degree.

Silencer Performance:

Silencers can reduce noise produced by air turbulence in a fan. However, only the airstream that passes through the silencer sees a noise reduction. Breakout noise through the fan housing and breakout noise through ductwork or flex connectors before the silencer will not see a reduction in noise. Vibration noise and mechanical noise generated by the motor and drive will also not be reduced by a silencer. Sound insulation or sound enclosures may be necessary to reduce noise levels that are outside the influence of a silencer.

IATC fan sound ratings are estimated for (8) octave bands. Our sound data is estimated using generalized conditions for field, directivity, airflow and silencer termination, including distance and angle relative to the listener. Prudent design techniques would dictate that these default values be reviewed by the customer since many calculations are dependent on specific site conditions.

Customer specifications asking for specific fan sound levels are difficult if not impossible to guarantee. Site conditions, adjacent reflecting surfaces, other sources of noise, all make it extremely difficult to predict final noise outcomes. If this level of assurance is required, we recommend our customers consult with a qualified acoustical sound engineer that can evaluate all system factors.

Silencer Maintenance:

To ensure proper operation over its life, a silencer should be visually inspected at least once a year to verify:

- Perforated acoustic internals are undamaged, remaining parallel and true.

- Airspaces between the acoustic splitters are free of any debris.

- The holes in the perforated steel are open and free of dust or other foreign material.

- In the event that debris must be cleaned from the airspaces or the perforated metal, the silencer should be vacuum-cleaned or wiped clean with a cloth dampened in a mild detergent solution.