Fan and damper applications may involve the handling of potentially explosive or flammable particles, fumes, or vapors. Such applications require careful consideration of all system components to insure the safe handling of such gas streams.

The AMCA Standard 0401 deals only with the fan and/or damper unit installed in that system. The Standard contains guidelines which are to be used by both the manufacturer and user as a means of establishing general methods of construction. The exact method of construction and choice of alloys is the responsibility of the manufacturer; however, the customer must accept both the type and design with full recognition of the potential hazard and the degree of protection required.

The use of the AMCA Standard in no way implies a guarantee of safety for any level of spark resistance. “Spark resistant construction also does not protect against ignition of explosive gases caused by catastrophic failure or from any airstream material that may be present in a system.”

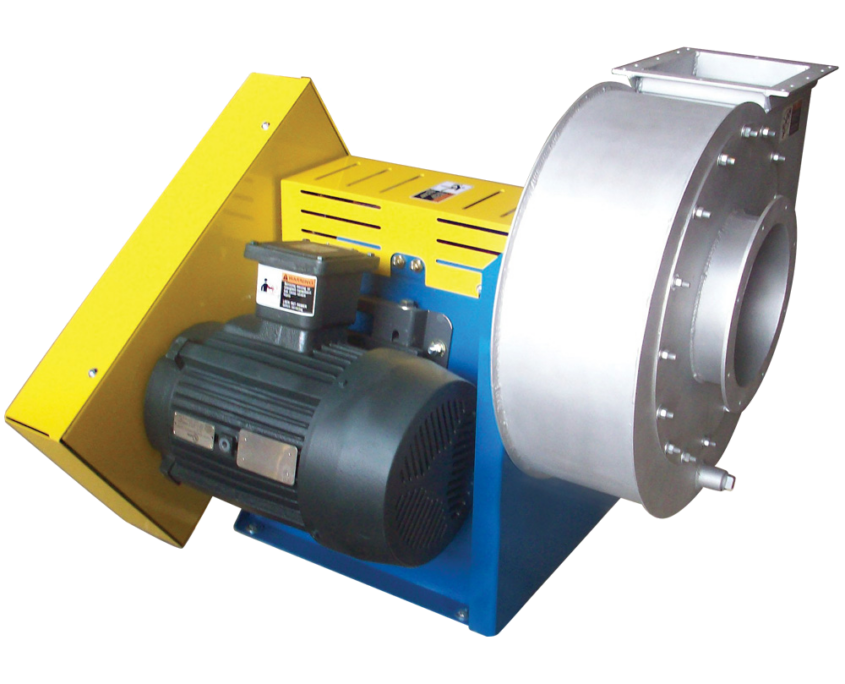

Spark A construction shown

AMCA A construction

All parts of the fan or damper in contact with the air or gas being handled and subject to impact by particles in the airstream shall be made of nonferrous material. Ferrous shafts/axles and hardware exposed to the airstream shall be covered by non-ferrous materials.

Fans only: Steps must also be taken to assure that the impeller, bearings, and shaft are adequately attached and/or restrained to prevent a lateral or axial shift in these components.

Dampers only: Construction shall ensure that linkages, bearings, and blades are adequately attached or restrained to prevent independent action. Ferrous containing bearings are acceptable if the bearings are located out of the airstream and shielded from particle impact.

AMCA B construction

Fans only: The fan shall have a nonferrous impeller and nonferrous ring about the opening through which the shaft passes. Ferrous hubs, shafts, and hardware are allowed provided construction is such that a shift of impeller or shaft will not permit two ferrous parts of the fan to rub or strike. Steps must also be taken to assure that the impeller, bearings, and shaft are adequately attached and/or restrained to prevent a lateral or axial shift in these components.

Dampers only: Construction shall ensure that linkages, bearings, and blades are adequately attached or restrained to prevent independent action. Damper blades shall be non-ferrous.

AMCA C construction

Fans only: The fan shall be so constructed that a shift of the impeller or shaft will not permit two ferrous parts of the fan to rub or strike.

Dampers only: Construction shall ensure that linkages, bearings, and blades are adequately attached or restrained to prevent independent action. Damper blades shall be non-ferrous.

Construction Notes

- No bearings, drive components or electrical devices shall be placed in the air or gas stream unless they are constructed or enclosed in such a manner that failure of that component cannot ignite the surrounding gas stream.

- The user shall electrically ground all fan and/or damper parts.

- For this Standard, nonferrous material shall be any material with less than 5% iron or any other material with demonstrated ability to be spark resistant.

- All structural components within the airstream, including non-metallic materials, must be suitable for conducting static charge safely to ground, thus preventing buildup of electrical potential. Dampers with non-metallic bearings must include means by manufacturer of transferring electrical charge from the blades to suitable ground.

- The use of aluminum or aluminum alloys in the presence of steel which has been allowed to rust requires special consideration. Research by the U.S. Bureau of Mines and others has shown that aluminum impellers rubbing on rusty steel may cause high intensity sparking.