IATC industrial dampers are used to control the flow of air through Centrifugal Industrial Fans. Dampers can be attached directly to fans, inlet boxes, or ducts. Many factors should be considered when choosing the appropriate damper for your application, such as airstream conditions, purpose and limits of airflow control, budget and even non-damper options such as VFD control. Additionally, each mounting position has its own operating characteristics which should be understood for a well-designed system and can effect fan selection.

All damper models are available in corrosion resistant stainless steel construction, aluminum, abrasion resistant material, or high temperature heat resistant alloys. Standard dampers can be modified to suit system design requirements not mentioned here. IATC is experienced at damper fabrication and can also build custom dampers to your design.

Inlet dampers

Dampers are often installed on the fan inlet as energy saving devices when the airflow needs to be modulated or run for extended periods of time at reduced flow. They are also effective for reducing the fan load at start-up or conditions with varying air densities.

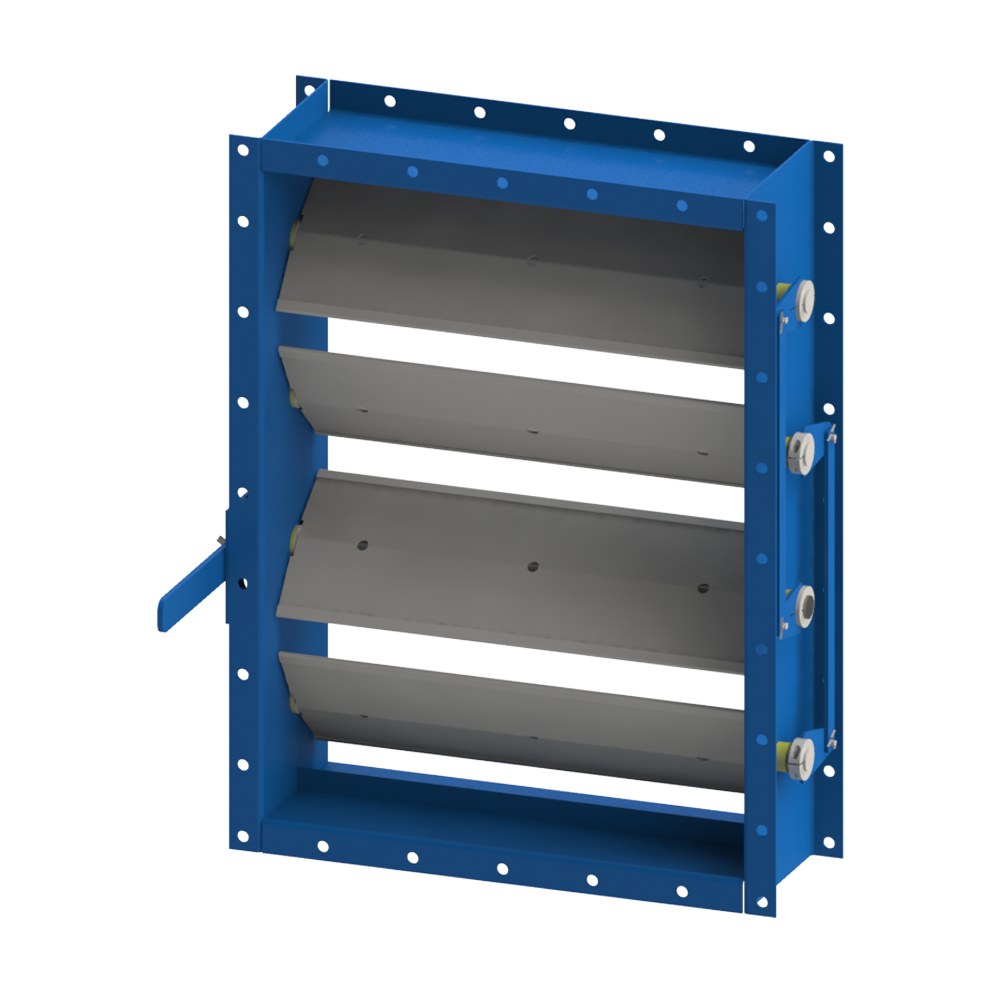

Parallel Blade

Parallel blade type inlet box dampers may be used to control the airflow through the system. The airfoil shaped blades are parallel to the fan shaft and remain parallel to each other as the damper is closed. Thus, in a partially closed position, a forced vortex with the same rotational direction as the fan impeller will be generated within the inlet box. The effect on the fan characteristics will be similar to that of a variable inlet vane control.

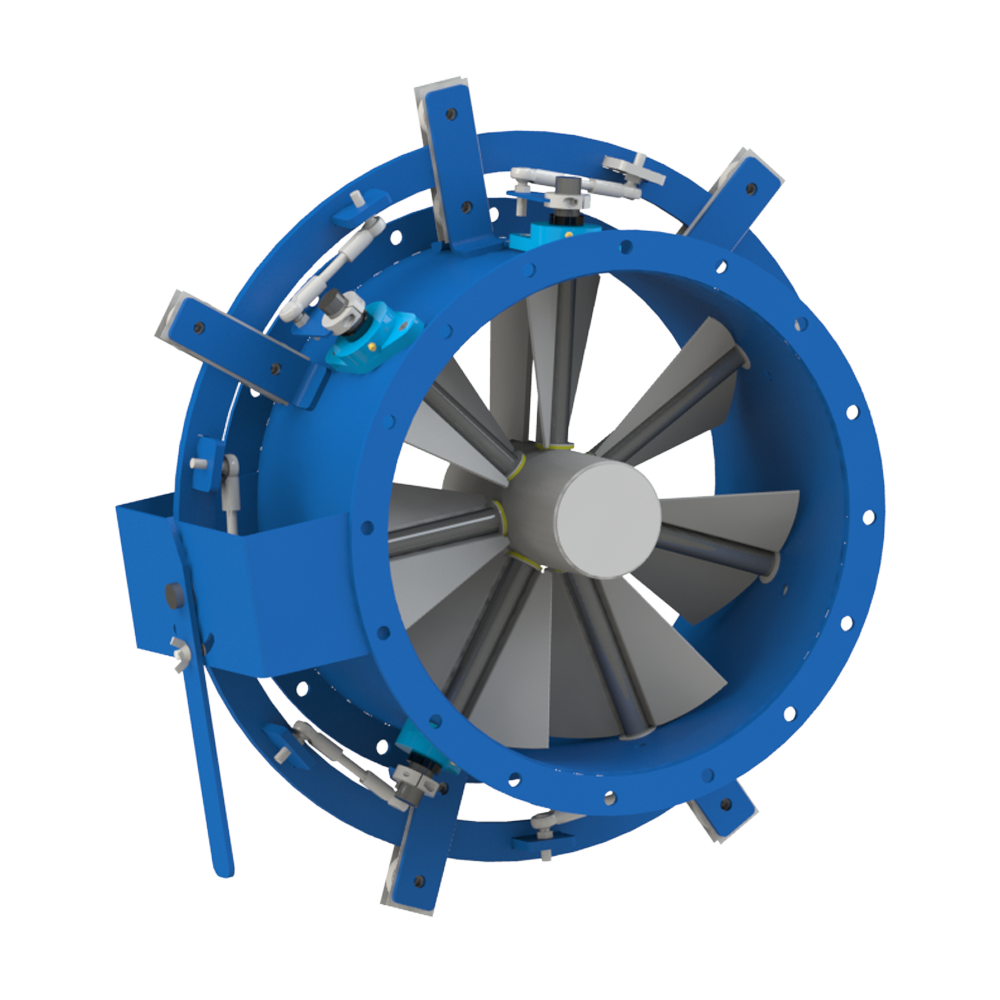

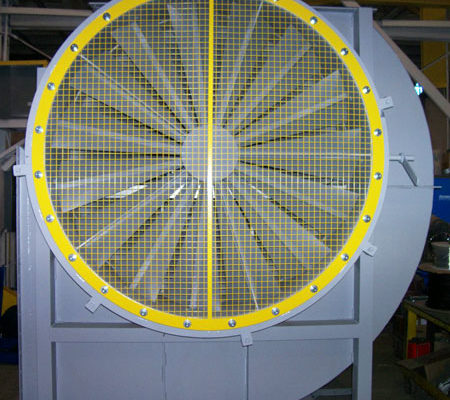

Variable inlet vane (VIV) dampers

Variable inlet vane dampers (also called vortex dampers) are mounted on the fan inlet to conserve fan horsepower at reduced airflow conditions. They are arranged to generate an inlet vortex (pre-rotation) in the same direction as the fan impeller, causing a reduction in power, consumption as the air flow is reduced. This type of control is most effective when the fan is expected to operate at reduced performance conditions for extended time periods or if the system requires modulation during operation. It will alter the fan operating characteristics and reduce the likelihood of instability. A wide-open VIV will produce a system effect which must be accounted for in the original fan selection.

Additional Options

- Aluminum construction

- Stainless steel construction

- High temperature construction

- Abrasion resistant construction

- AMCA spark A, B, C construction

- Pneumatic and electric actuators

Outlet dampers

Outlet dampers, also called volume control dampers, are basic elements which create a variable resistance within a system. If it is desirable to compensate for temporary air density or system resistance changes, an outlet damper may be appropriate. They are the least expensive, but also the least efficient of the traditional flow control devices. Because outlet dampers operate as a resistance in the system, they do not change the operating characteristics of the fan, but merely restrict its flow. Flow restrictions can cause Centrifugal Industrial Fan operation to become unstable and outlet damper use must be considered carefully. Due to efficiency and stability concerns, an outlet damper should not typically be used as a permanent flow restriction. IATC provides dampers for both ductwork and fan applications.

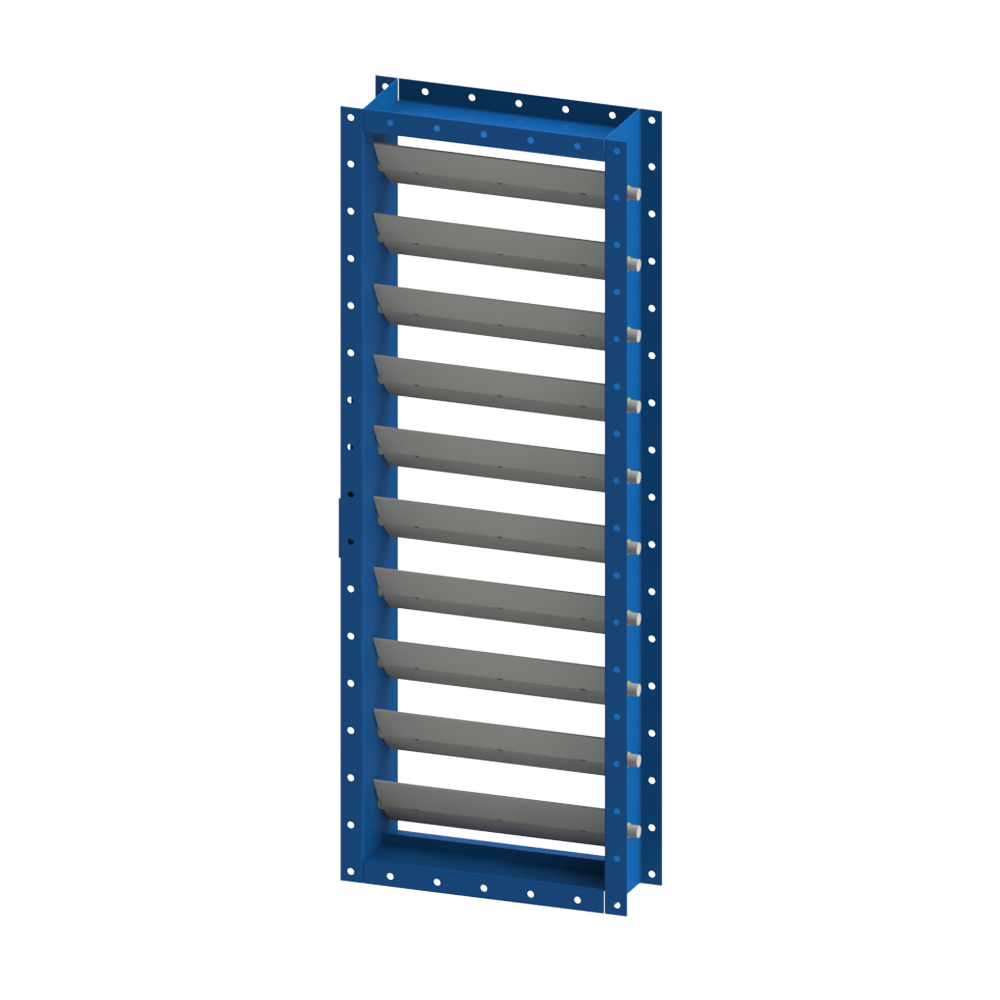

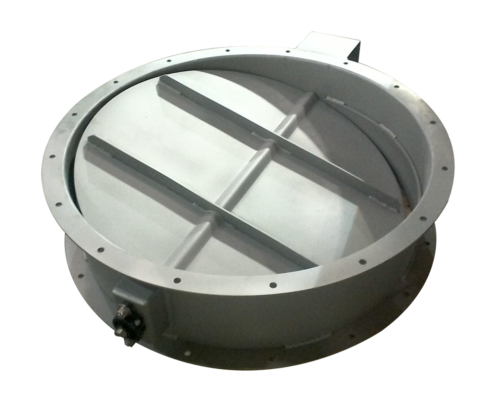

Opposed Blade

Opposed blade dampers are built such that adjacent blades rotate in the opposite, or opposed, direction. This style of operation is the best selection for an outlet damper because it offers good control over the entire operating range and maintains an even distribution of air downstream from the damper. The blades are airfoil shaped to minimize the flow restriction of the damper in the open position. Commonly used for cold starting on many air and process gas systems, opposed blade dampers maintain even air distribution downstream of the damper.

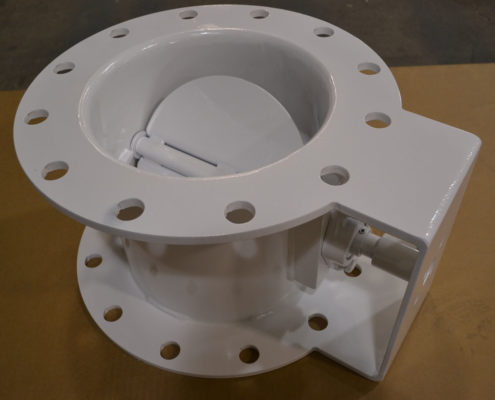

Butterfly Dampers

Although butterfly dampers are normally associated with ductwork, there are applications in which they have been successfully used on the fan outlet. Generally, the damper would be wide open during normal operating conditions and closed only occasionally, such as at start-up. The fan typically would have a smaller outlet area, and produce a relatively low volume of airflow. IATC provides butterfly dampers for both ductwork and fan applications.